Years Brand Promise

Let’s Build your future today

Steel Billet Making

TMT Bar Rolling Mill

CALL FOR SERVICES

Steel Billet Making

High Quality

High quality raw materials are charged into the Steel Melt Shop furnace and heated upto 1650℃. The molten metal is treated with Inert gasses to release dissolved gasses present in the liquid metal. The Liquid steel is casted into steel billets in Continuous Caster Machines.

Founded in

1979

SELF-TEMPERING

After the rebars leave the quenching station, the temperature of the outer layer suddenly decreases from 900 ℃ to 280 ℃ and the temperature on the inner core of the bar remains the same. Therefore the inner layer tempers the outer layer. Hence the outer Martensite rim transforms into Tempered Martensite; an intermediate ring of Martensite and Bainite is also formed.

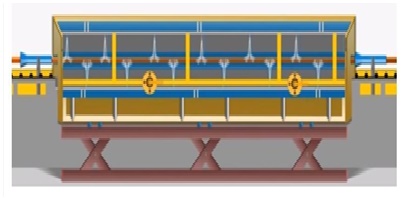

TMT Bar Rolling Mill

QUENCHING

QUENCHING

The red hot steel bar is sent to a quenching station where water is continuously sprayed onto the incoming bar through special spray nozzels. This results a rapid change in temperature in the outer layer of the steel bar whereas the temperature on the inner core remains the hot. Thus Martensite rim is formed in the outer layer of steel bars.

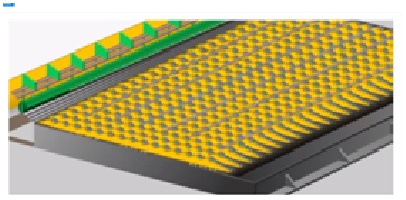

ATMOSPHERIC COOLING

The Thermo Mechanical Treatment (TMT) Rebars are cooled slowly on automatic cooling beds to attain equalization temperature. The core is transformed to a Ductile Ferrite – Pearlite structure.

This process results in the formation of a hard outer layer which keep the bar strong and a soft inner layer to provide ductility to the bar.